Custom Industrial Machine Design Services

MJ Engineering is one of the best custom machine design/build firms in the area. We design, build, and test all of our cells in house. Our process, while complicated, is designed to give the customer the best machine possible. This equipment is needed to make jobs easier or more productive. Sometimes it may be improving the quality of the products or a packaging machine. Either way, you get a machine designed specifically for your process. Many companies utilize MJ Engineering because of our professionalism, consistency, and competency. Since custom industrial machine equipment is expensive, you want to know that the company you are choosing to complete your project has your best interests in mind. That’s a guarantee we make at MJ Engineering. We will give our opinion of what we think you should do and take in what you want to do and try to give you the system that best fits your needs and wants. Clients get hard working engineers who are proud of their machines, which means we will make sure they work properly before they are sent to the customer.

Contact us today to learn more about our custom machine design and engineering services.

Our Custom Machine Design Philosophy

At MJ Engineering we focus on finding the best method to address an issue our clients are having. We minimize our time and maximize our efficiency to give our customers the best product possible in the shortest time possible. We have been in business for over 35 years and have been providing our services to countless manufacturers across Ohio, Indiana, Illinois, Kentucky, Michigan, Pennsylvania, and West Virginia.

We Design Custom Machinery for a Variety of Industries and Purposes:

Industries and applications include:

- Chemical Processing

- Medical and Pharmaceutical

- General Manufacturing

- General Palletizing Applications

Our Custom Chemical Processing Machinery Can Include Features Such As:

- Servo gripper EOAT to ensure too much force/pressure isn’t applied to fragile items.

- EOAT is designed with a positive locking mechanism so the part can be rotated into any orientation, be it dumping product, filling, or just picking/placing.

- Equipment designed/built to handle high temp environments and dusty dirty atmospheres.

- Robot controllers can be located in a climate-controlled environment for dirty/dusty environments.

- Integrate vision systems to accommodate movement of parts due to thermal cycles.

Our Custom Palletizing and Depalletizing Machinery:

- Can often be industry non-specific

- Can handle vacuum, magnetic, gripper, or other EOAT designs based on project constraints

- Can incorporate pallet dispensers or stacks of pallets brought by forklift

- Can incorporate tier sheet dispensers or stacks of tier sheets with methods to break vacuum

- Can handle wood pallets, plastic pallets, chep pallets etc…

- Can handle boxes that are taped or glued, can handle tanks, and even small parts like vials.

Our Engineering Capabilities and Expertise

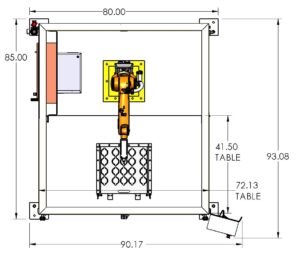

At MJ Engineering, we can handle anything from robotic automation to gantry-based systems to conveyor systems. These types of automation projects can be customized or replicated. However, every plant is different and not one plant has the exact same dimensions or layout, meaning that every single cell has to experience a certain amount of customization. MJ Engineering has helped countless companies across the midwest speed up and automate their processes. This can include, but is not limited to, total and partial automation. The less human interaction, the more consistent the products and cycle times will be.

Services Overview

Our Engineering Capabilities:

- Professional Engineering Work

- Amusement rides and attractions (park and portable) both design and evaluation per ASTM

- Fire Truck ladders, outriggers, turntables per NFPA

- Mining Canopies Approvals per MSHA

- Roof bolter Approvals per MSHA

- Cranes per ASME

- Lifting devices per BTH standards

- Miscellaneous

- Finite Element Analysis

- SolidWorks CAD

- Custom machine design

- Automation Control System design/build

- Hydraulics/Pneumatic systems

- 3rd Party Corrosion Inspection

- PLC/HMI programming

- Vision inspection systems