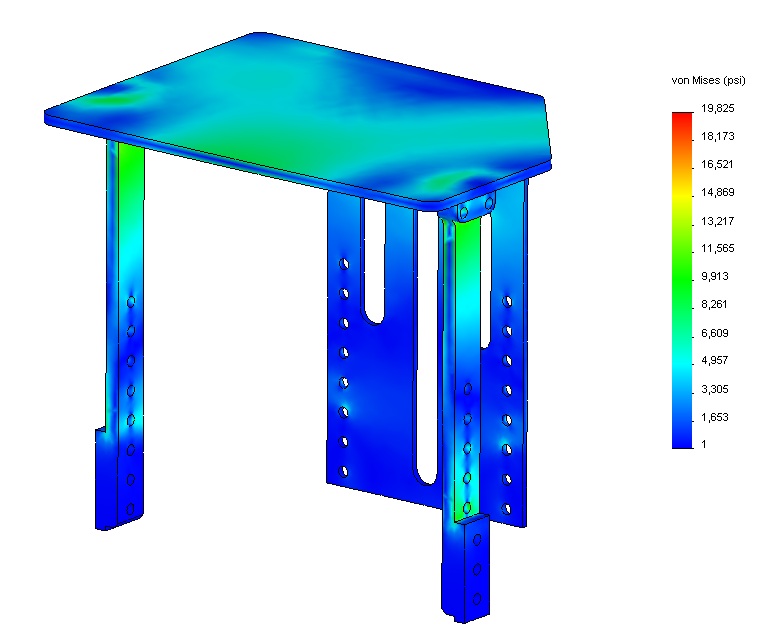

Finite Element Analysis of Shuttle Car Canopy for the Mining Industry

Using finite element analysis (FEA) we tested the shuttle car’s canopy and provided the needed engineering design to guarantee that the canopy conformed to MSHA standards and load ratings. Because of MJ Engineering’s outstanding design team, our customer was able to avoid the difficulties and cost of purchasing and maintaining FEA software and having to keep a professional engineer on staff. As always MJ Engineering also provided our client independent design advice and an industry leading level of customer support.

If you have any questions about this project or any of our other services please contact MJ Engineering or check out the details listed below.

Project Description

MJ Engineering Analyzed the Canopy Design of a new mine shuttle car, verifying that it conforms to mining standards.

Capabilities Applied/Processes

Performed Finite Element Analysis (FEA) in SolidWorks’ Simulation

- Analyzed Operators Canopy

Design/Engineering

- Provide Engineering Design to Bring Canopy into MSHA Standards

- P.E. Certification of Canopy

Features/Benefits

Process Requirements

Must Conform to MSHA Standards

Benefits

- Customer has no need to purchase and maintain a copy of FEA software

- Customer receives independent design advice & review

- Customer does not need professional engineer on staff

More Info

Industry for Use

Mining

Delivery Location

West Virginia

Standards Met

Mining Safety & Health Administration (MSHA)

Product Name

Finite Element Analysis of Mine Shuttle Car Canopy