Quality Services and Products

Applying state-of-the-art technology to industrial operations since 1988.

Request a Quote

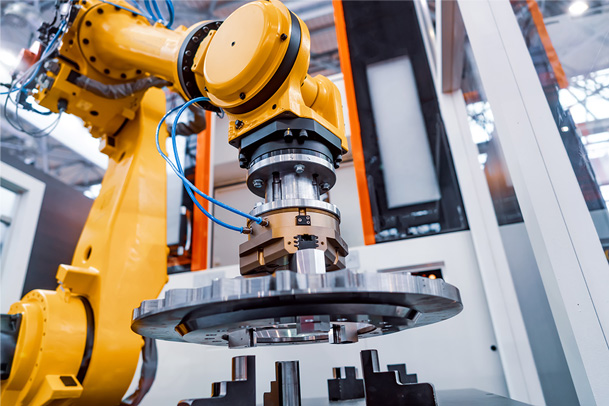

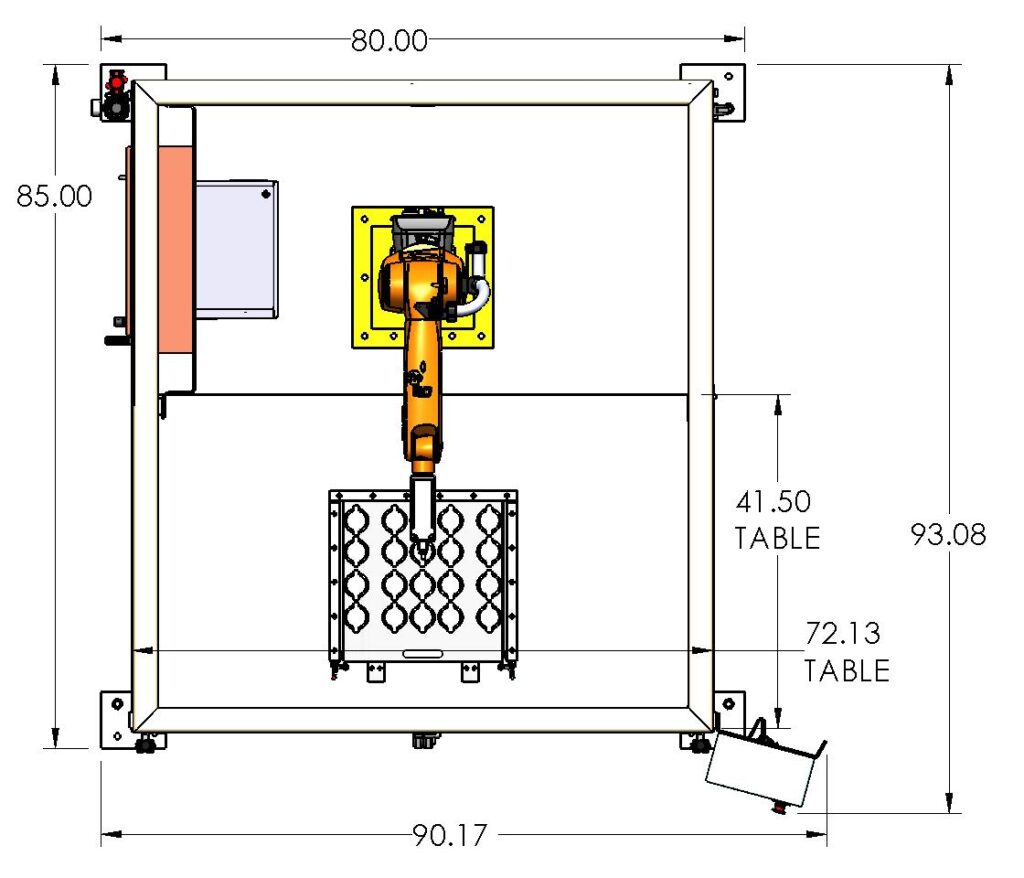

Robotic Systems Integration

MJ Engineering has extensive experience as a factory-authorized robotic systems integrator. We work with FANUC robotic systems to integrate robots with a wide variety of applications.

Engineering Services

MJ Engineering focuses on mechanical design to create the most useful, efficient machine possible.

Manufacturing

MJ Engineering offers 3D printing services and can create parts as needed, much faster than a machine shop.

Qualified Engineers and Designers

At MJ we utilize many design and analysis software packages to assist with the engineering process. Of our designers and Engineers, 85% have achieved the Certified SolidWorks Professional (CSWP) or Certified SolidWorks Associate (CSWA) status from SolidWorks. Each CSWP/CSWA has proven their ability to design and analyze parametric parts and moveable assemblies using a variety of complex features in SolidWorks. We also utilize many other design and evaluation software packages:- SolidWorks Simulation (Formerly COSMOS)

- Pro Engineer

- Solid Edge

- AutoCAD Electrical

7

3D Printable Materials

85

Percent CSWP/CSWA Certified

35

Years of Excellence

10

States Served

Trusted by Many Industries

At MJ Engineering, our robotic and automation expertise is, quite simply, unsurpassable. Whether it’s a custom-designed robotic cell that you require, or whether you need analytic insight into the implications for a particular piece of machinery, we are your go-to source. We’ve worked with automotive, mining, glass, plastics, off-road equipment, pharmaceutical, food and beverage, pet food, agriculture and transportation industries. View some of our projects below:Latest News

- Quarterly Newsletter 2021:Q4Robotic Integrators tend to develop niche’s through their experiences. MJ Engineering is no different. We have developed a niche serving the powder processing industry with our robotic sagger handling cell. We have robotic solutions that can handle multiple different kiln styles including roller kilns, tunnel kilns and shuttle kilns. A single robot system is capable of handling 1400- 1500 saggers per day depending on the needs of the system. A two robot system can handle 2000 saggers or more per day. The robots use a proprietary EOAT (end of arm tool) that will not over squeeze the saggers because ceramic saggers don’t handle compression well. Overall the robot system can be integrated with dump stations, fill stations and crack inspection systems to remove saggers before they fail. The systems are designed to run 24 hours a day with little to no human interaction. Through our experience, we have found that robotically handling saggers increases the life of the sagger substantially.

- County FairsMJ Engineering has started providing third-party support on amusement rides at a number of Ohio county fairs. The engineering team has been working closely with State of Ohio ride inspectors, ride owners, and operators to review documented instances of ride corrosion and fatigue. Our engineers have been able to facilitate discussions with ride manufacturers and provide expert opinions on the effects that specific instances of corrosion and fatigue create on the overall ride structure, and most importantly, the safety of the ride.

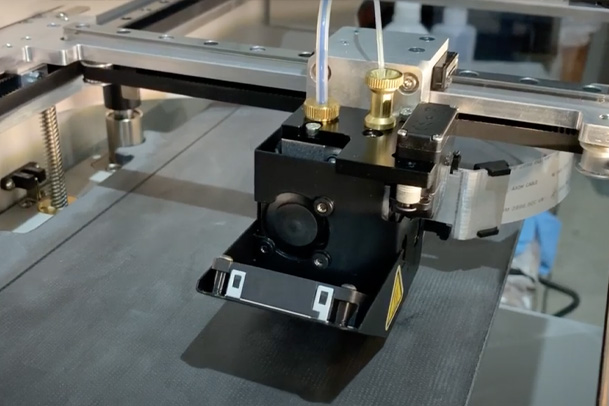

- Backlit Conveyors SystemsEngineers are responsible for coming up with creative solutions to problems that customers have and MJ Engineering is no different. Oftentimes that problem revolves around how to increase production and decrease labor costs. Palletizing and depalletizing cells are a quick and easy way to streamline a process that cuts out labor and increases productivity. However, when you have a product that needs to be inspected the process can be far more complex, and often it is easier to leave a person in charge of that process. One method for part inspection is through the use of a vision system. To enhance the capabilities of vision systems, MJ integrates them with our own specially designed backlit conveyor.

Featured Videos

- “What is design innovation? And how do we use it to ensure the success of our clients? Watch the video to see how we use design innovation to design the latest most high tech robotic vision systems.”

- Engineering Frenzy – Amusement Ride