Robotic Automated Depalletization Systems

Robotic Depalletization Saves Firms Time, Reduces Mistakes, and Increases Productivity

MJ Engineering excels at robotic palletizing and depalletizing cells. In palletization cells, a robot is used to pick items off of the line and put them onto a pallet. This process is very deliberate and calculated. We have performed this task many times.

A few examples would be a propane tank palletizer, bag palletizer and saggar palletizer/depalletizer. Depalletization cells, however, are just the opposite. You pick up parts and put them onto some kind of line to have the parts begin, whatever their process is. Most of the time the parts are placed onto an outgoing conveyor. A good example is a bottle depal cell. Bottles came on a pallet in a cardboard box and we had a robot reach in and pick the bottles out and put them onto an outgoing conveyor which moved the parts down to an indexer.

Automating a two or three shift operation can have efficient payback of the investment. Additionally, it can prevent repetitive injuries due to poor ergonomics of bending over reaching into boxes or lifting heavy objects all day. Robots are more consistent and can be faster than human operators. You don’t have to pay a robot for breaks or sick time.

Contact us today to learn more about our solutions for depalletization.

Robotic Depalletization Saves Firms Time, Reduces Mistakes, and Increases Productivity

For large companies running 2+ shifts robots prove their worth extremely quickly. The rule of thumb is if you run 3 shifts robot ROI is 1, yes 2+ shifts 2 years and 1 shift 3+ years. Robots eliminate the need for an operator to make a judgment call. Robots are programmed to make the same decision every time, which gives you the ability to alter your current process to fit what the robot is going to do. Robots don’t take breaks, they also don’t get distracted, which means parts are constantly being moved as long as the queue is full.

Custom Programming and Design for Your Automated Depalletization System:

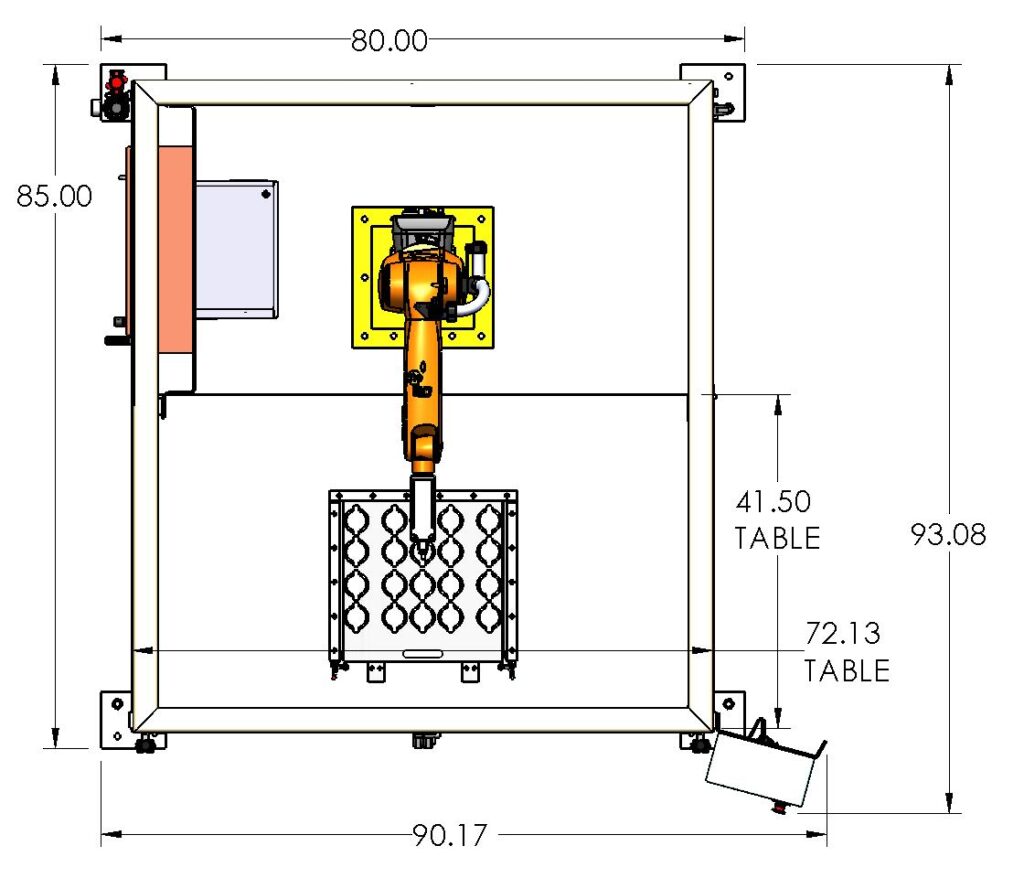

At MJ Engineering we take our time to guarantee our customers get a cell that best fits their needs. We will come out to your plant, look at what is currently being done and return to our office and design something that fits into the space provided and will work in a way that achieves or exceeds what is currently being done.

Once we have our design, we will meet with the customer to review our design and get final approval. This process allows us a deeper dive into the important things the customers are looking for and to be able to show the customer a design that will work while finding things that may need to be changed.

We Use the Best Robotic Systems Available

MJ Engineering is a tier 2 licensed Fanuc integrator. We are also licensed integrators for Kuka and Epson. We also have used collaborative robots like UR and Omron (Techman) robots on projects recently and are beginning to see the ask for those increases.

The robot that gets chosen for a project will be a function of several points. First, if the customer has standardized on a particular brand, we will use that. If we get to choose, our first choice would be industrial and most likely Fanuc as they have the best range of products and the best service/support network in the country.

If you are looking for assistance with palletizing or depalletizing, you want to turn to the experts. By calling or emailing MJ Engineering you are doing exactly that. Put your trust in a firm who will put you first. Call MJ Engineering Today to kick off your project.