Industrial Automation Engineering Services

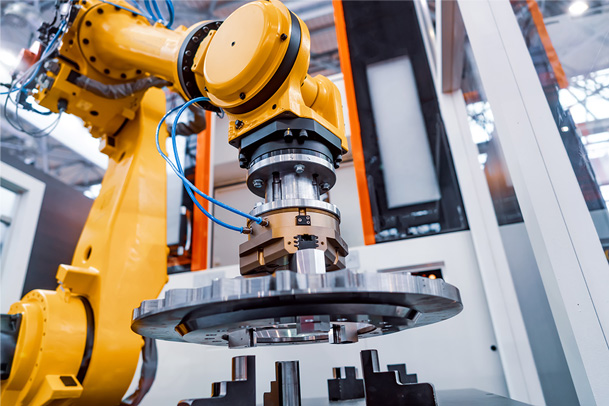

Robotic Depalletization Saves Firms Time, Reduces Mistakes, and Increases Productivity

MJ Engineering has been providing the manufacturing industry with automated solutions since 2006. At MJ Engineering, we custom build a solution for every customer. With years of experience in house and a 15,000 sq. ft. attached shop, MJ Engineering will take on your project, build it in house and provide a run-off to make sure the system is working prior to shipping. The system is then shipped and installed by our team at your site. Choosing MJ is choosing the company who will take the time to make sure the customer gets the best system for their needs, robotic or non-robotic. We specialize in the following applications:

- Pick and place

- Palletizing and depalletizing

- Part and product manipulation

- Safety control

- Line tracking

- Routing

- Drilling

- Sagger Handling

- Vision Systems

- Robotic Assembly

Contact us today to learn more about our solutions for industrial automation.

Automated Manufacturing: What Are the Benefits?

Automating your process comes with many benefits. By automating your process you can:

- Reduce and repurpose operators

- Increase production

- Increase safety

- Increase reliability and repeatability

- Avoid issues caused by worker shortages

Factory Automation Integration:

Integration of a robotic cell happens in steps.

- Step 1: After the build portion of the project is completed. MJ Engineering will provide a run-off at our own facility. The point of this step is to prove to the customer that the cell works and meets the requirements set forth by the customer in the specs.

- Step 2: MJ Engineering puts all of the equipment on pallets and ships it to the factory it is going to be permanently installed in.

- Step 3: Once the equipment arrives and has been unloaded, MJ Engineering will send our install team to the site to reassemble the equipment to the same condition it was in at our shop.

- Step 4: Once reassembled and hooked up, MJ Engineering will provide the customer with one more runoff to verify that the cell is working properly. This gives us a chance to make sure that everything fits in the space provided and that nothing gets broken in the shipping process.

- Step 5: Once the specs of the project have been met at the customer’s facility, the project is deemed complete.

Once we have our design, we will meet with the customer to review our design and get final approval. This process allows us a deeper dive into the important things the customers are looking for and to be able to show the customer a design that will work while finding things that may need to be changed.

Automated Manufacturing Services Based Out of Central Ohio

MJ Engineering has been integrating robots into manufacturing facilities since 2006. We can handle projects ranging from $100k to $1,000,000+. We can handle robot cells that utilize industrial or collaborative robots. We are licensed integrators for Fanuc, Kuka, and Epson. Once we land a job from a customer, the likelihood of them choosing us for other projects skyrockets. Our customers appreciate our clarity, low cost, and reliability.

If you are looking for a reliable, and exceptional engineering firm to assist in robotic integration into your factory, reach out to MJ Engineering. You won’t regret your decision to choose MJ Engineering.