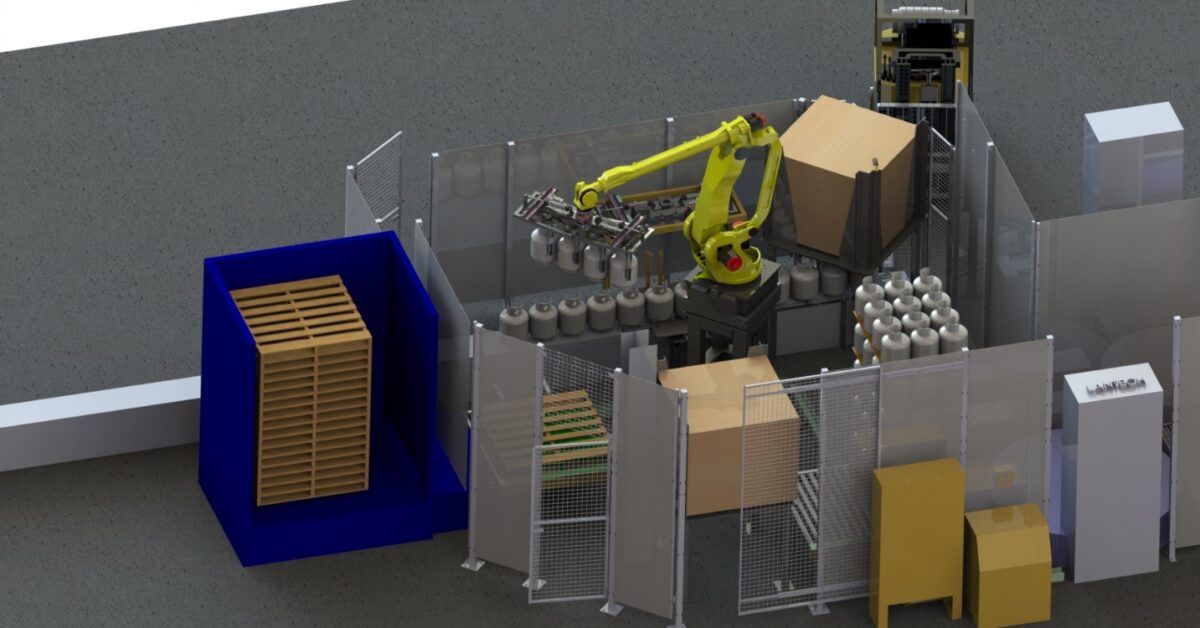

Custom Designed Robotic Cell Tank Palletizing

The cell interfaces to a pallet dispensing system and pallet wrapping station to complete the fully automated tank palletizing process.

The robot EOAT (End Of Arm Tool) is designed to handle the tanks, tier sheets and pallets. The pallet building process starts with the robot picking and placing a pallet in the stacking position. The robot then picks tanks and tier sheets as needed to build subsequent layers.

Additional support was provided to the client for controls and programming of the conveyor and pallet dispenser.

Project Description

This custom designed robotic cell is used for picking and palletizing propane tanks, both 20 and 30 pound sizes.

Capabilities Applied/Processes

Cell Design

- Conception of cell that meets unique production requirementsand existing floor plan configuration.

- Create SolidWorks© 3D models of cell concept/li>

Tooling Design

- End Of Arm Tooling (EOAT) Design/li>

Installation

Start-Up

Operator and Maintenance Training

Features/Benefits

Features

- Utilizes FANUC© M410/140iB

- Individual tanks are delivered into the cell via the common chain conveyor.

- Automatic tool changer to allow handling of boxed and un-boxed tanks./li>

Benefits

- Provides speed and consistency that is not capable w/ manual procedures

- Reduces the need for operators to manually handle tanks during the process.

- Capable of picking 20 lb and 30 lb tanks, both boxed and un-boxed.

- Automated pick and place of tanks, pallets and tier sheets using a single multi-purpose EOAT design./li>

More Info

Overall Cell Dimensions

180″ x 130″

Size Capabilities

20 lb and 30 lb, boxed and un-boxed propane tanks

Tightest Tolerances

+/- 0.2mm

Material Used

None

In Process Testing Performed

The gripper system utilized on the EOAT was tested prior to installation of the cell in the plant.

Pre-Ship runoff of a full pallet of tanks was provided at the MJ Shop prior to shipping to the customer site.

Industry for Use

Consumer products

Delivery Location

Westerville, Ohio

Standards Met

Customer supplied print, 2D Auto CAD Drawing

Product Name

Custom Designed Robotic Cell Tank Palletizing