Collaborative Pick and Place

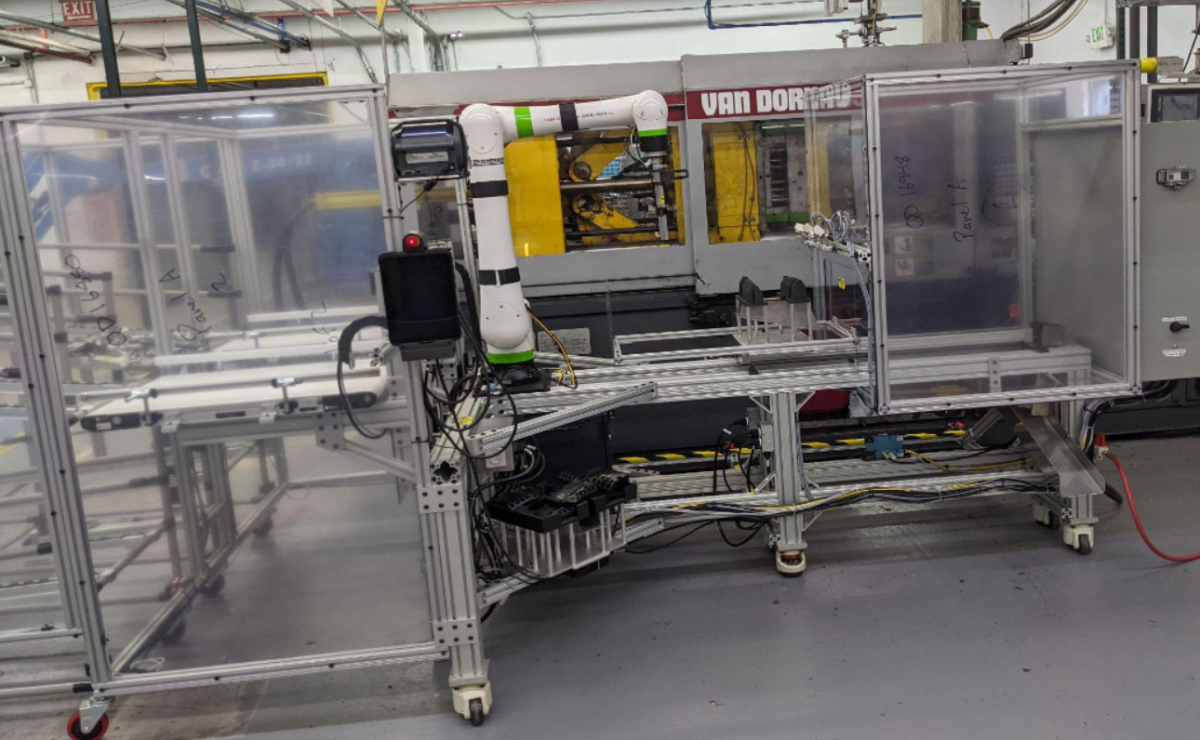

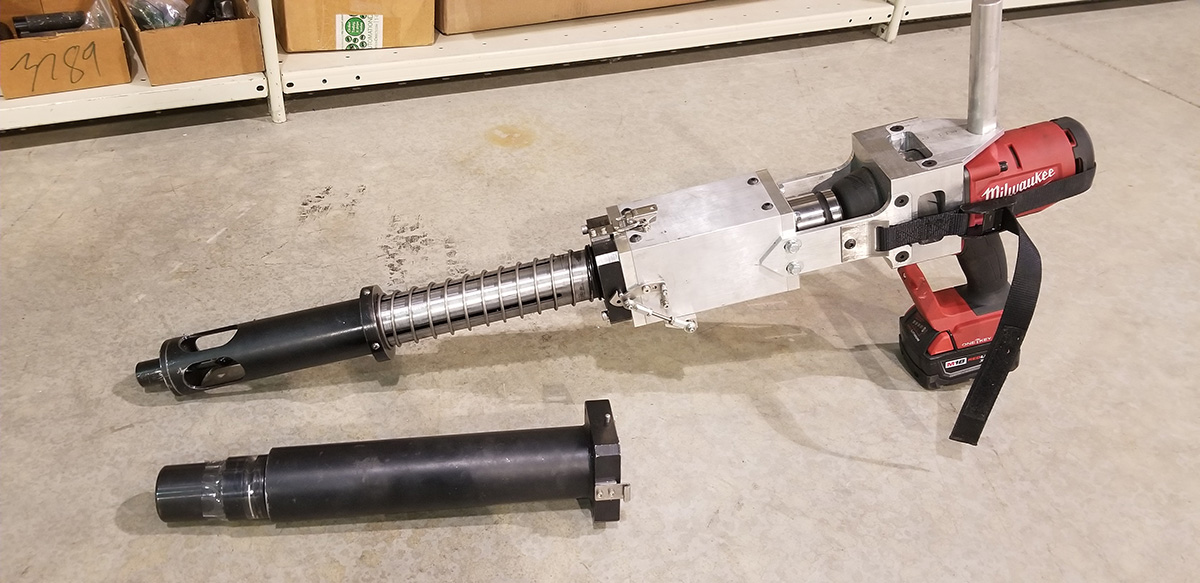

The system utilizes a vacuum end of arm tool that picks the plastic parts and places them in totes. Once placed into totes the robot picks a label and places that on the top rim of the tote. The tote is then ejected out from the station via a sublevel conveyor and the operator is then responsible for placing the label on the tote.

The system has powered conveyors to bring in totes in the center and gravity conveyors to eject full totes. There are right-hand and left-hand parts (mirrors of each other), in order to assist the operator, the output conveyors are separated to help prevent mix-ups of left/right-hand parts. While the cell was originally designed as a collaborative cell, the speed limitations were considerable with everything the client was wanting the cell to do. We

added some guarding and light curtains to allow the cell to run in non-collaborative mode.

Unfortunately, running a collaborative robot in a non-collaborative mode creates significant safety issues and concerns when attempting to meet industry standard safety standards such as RIA. There are various ways to allow this, including safety area scanners, light curtains/fencing, and radar scanners. Collaborative robots are often sold through distributors who don’t understand the safety impacts of integrating a collaborative robot in your facility. They expect you to understand all the requirements and take all the risks.

Come talk to us about your “collaborative” application and get a real perspective on what that means. To see how MJ Engineering can help you, please contact us today!