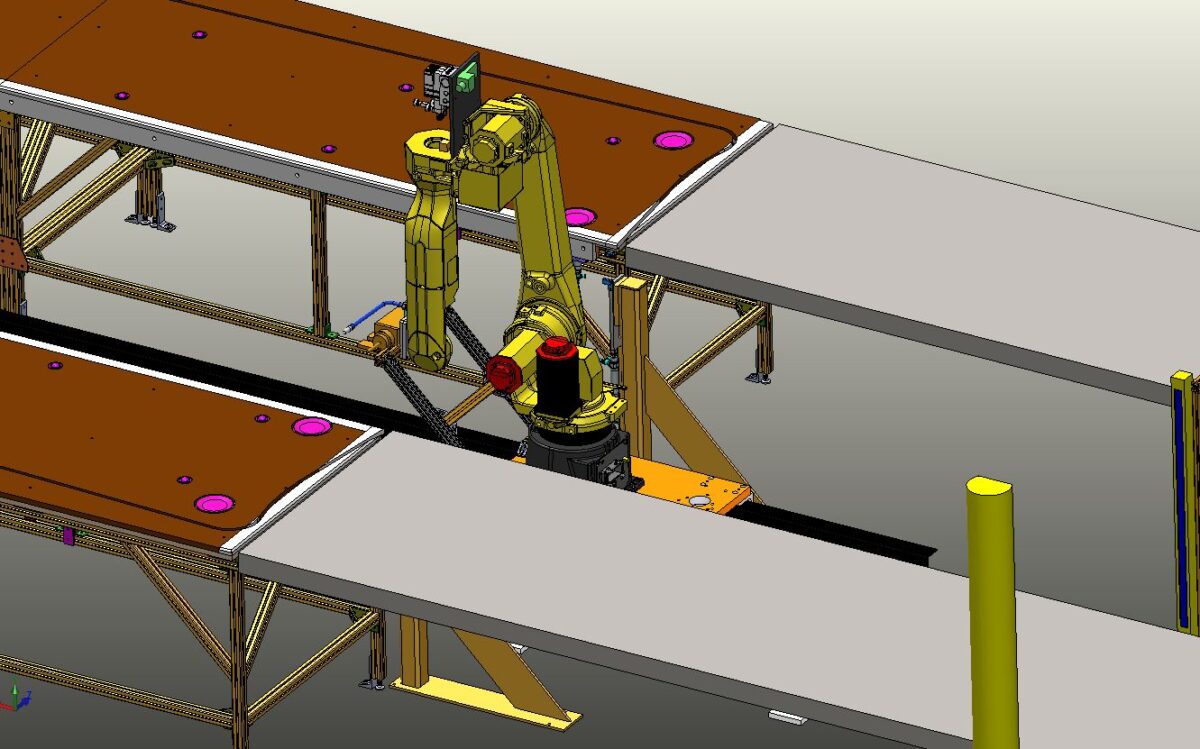

Custom Designed Fiberglass Processing Robotic Cell for the Truck Industry

Design elements of the fiberglass processing robotic cell include a FANUC M20iA 6 axis robot that allows for processing of panels up to 30′ long and 4′ wide, and high-speed production capacity, such as three-dimensional fiberglass routing and automated tool changing. Meeting the demanding production requirements set by the customer, including 385 holes drilled and 750 feet of panel processed per hour, we also designed the cell for ±0.125″ positional repeatability in all processing operations. As required, we also produced electronic documentation as well as training. This particular design allows the customer to adjust the robotic operation for new products, adding to the cell’s efficiency and capability.

Project Description

This Custom Designed Fiberglass Processing Robotic Cell is used to process fiberglass for a manufacturing application.

Capabilities Applied/Processes

Cell Design

- Conception of Cell that Meets Unique Production Requirements

- Create SolidWorks 3D Models of Cell Concept

- Time Study Simulations

- Utilizing FANUC’s Robot Simulation Software

Installation

Start-Up

Documentation

- Complete Electronic Documentation Package Provided

Training

- Operations & Maintenance Training

- Engineering Training

- Allows Customer to Train the Robot for New Products As Required

Features/Benefits

Features

Utilizes FANUC M20iA

- Mounted on a 7th axis Güdel Linear Track

- Allows for Processing of up to 30′ Long Panels

- ATI Tool Changer is Utilized

Hi-Speed Production of Fiberglass

- Routing of Fiberglass Panels in Three Dimensions

- Over 385 Holes Drilled & 750 Linear Feet of Panel Processed Per Hour

- Automated Tool Changing-Up to 4 Unique Tools

Benefits

- Meet High Demanding High Production Requirements

- Ability to Program Specific Shapes in the Robotic Control System

- Eliminates the Need for Fixed Custom Made Templates/li>

More Info

Overall Cell Dimensions

Length: Up to 30′

Width: Up to 4′

Height: 6″

Overall Cell Dimensions

Length: 40′

Width: 25′

Height: 6′

Tightest Tolerances

+/-0.125″ Positional Repeatability Over Full Length

Material Processed

Fiberglass

Industry for Use

Truck

Delivery Location

Ohio

Standards Met

Customer supplied specifications

Product Name

Custom Designed Fiberglass Processing Robotic Cell