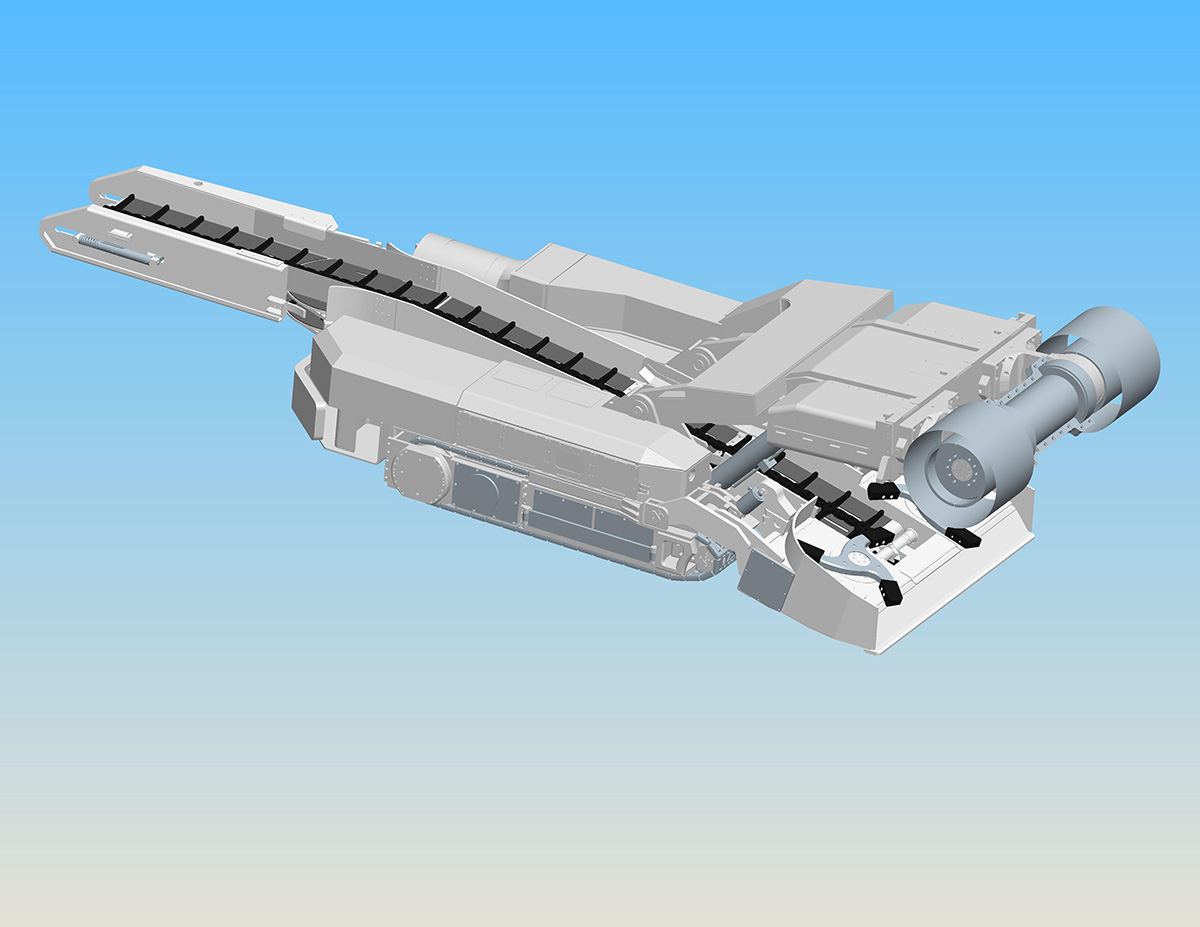

Engineering of Continuous Miner for the Coal Mining Industry

We began by designing the miner using Pro/ENGINEER software to create a 3D CAD model. Our design team also provided the client with a complete drawing package including a BOM and aided in selecting and procuring the OEM parts.

The continuous miner, which has steel with chromium carbide overlay in the conveying path, meets all MSHA and ATEX safety requirements. It is also capable of mining up to 14.5’ high coal and comes with a remote control pendant and the latest in motor control systems technology.

To find out more about our engineering and design service please contact MJ Engineering. For more information about this specific project please see below for details.

Project Description

MJ Engineering Engineered a new Continuous Miner that could compete in the market using the latest technology while maintaining cost effectiveness.

Capabilities Applied/Processes

- Design/Engineering

- Designed Miner Using 3D CAD Modeling within Pro/Engineer

- Provided Complete Drawing Package Including BOM

- Lead Engineering in Design Group

- Aided in Selecting & Procuring OEM Parts

- Finite Element Analysis (FEA)

- Performed FEA on Major Components

- Meet MSHA & ATEX Safety Requirements

- Mine in a 9’ to 14.5’ High Seam

- Latest Technology in Motor Control Systems

More Info

Overall Dimensions

Length: 40’

Width: 12’

Material Used

Steel Plate & Bar: T1, A36, AR 400, A572 Gr. 50 and Chromium Carbide Overlay.

Steel Tubing: A500 Gr. B

Industry for Use

Coal Mining

Standards Met

Customer supplied specifications

Mining Safety & Health Administration (MSHA)

ATEX

Product Name

Engineering of Continuous Miner